Our Products

Pail, Cylindrica, Rectangular, Square Cans & Printing Tinplate.

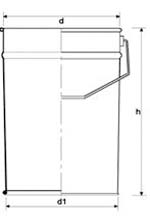

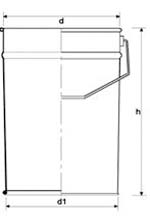

Pail Cans

From 3,5 lt. to 25 lt., the metal cans’ Europack answer to the needs to the Chemical, Food and Petroleum Industries.

-

Go To Gallery For More

Full automated Pail Production Line for UN. Pail:

Super Wima side seam welding with an overlap of 0.8 mm.

Side seam welding coated by electrostatic powder inside, and lacquered by sprayed clear varnish from the outside to prevent any rust spot.

Top edge of pail is double curled to withstand high stresses.

Triple bottom seaming.

Two side “ears” are welded or riveted to the body, and a galvanized wire bail handle is attached.

Handles are furnished with, or without a grip, which is usually a contoured plastic.

All can’s components could be from 0.29-0.33mm.

Could be one or two beading according to customer’s request

Revolutionary injection system for compound sealing base & PVC compound sealing for the top.

Customer’s selection of decoration and inside coating.

Semi-automatic Pail Production line:

Wima side seam welding with an overlap of 4 mm.

Side seam welding coated by Air dry Clear lacquer.

The top edge is single curled.

The double bottom is seaming.

All can’s components from 0.27-0.30 mm.

Standard characteristics

| Capacity (lt.) |

Upper Diameter (mm). |

Lower Diameter (mm). |

Height (mm). |

Tinplate Thickness (mm). |

Cans per pallet. |

Notes. |

| 3.5 |

198 |

182 |

160 |

0.23-0.27 |

500 |

Lug Lid |

| 4 |

198 |

182 |

170 |

0.23-0.27 |

500 |

Lug Lid |

| 5 |

198 |

182 |

200 |

0.23-0.27 |

500 |

Lug Lid |

| 6 |

198 |

182 |

245 |

0.23-0.27 |

500 |

Lug Lid |

| 7 |

198 |

182 |

270 |

0.23-0.27 |

500 |

Lug Lid |

| 10 |

292 |

271 |

210 |

0.28-0.33 |

228 |

Lug Lid |

| 12 |

292 |

271 |

250 |

0.28-0.33 |

228 |

Lug Lid |

| 15 |

292 |

271 |

290 |

0.28-0.33 |

240 |

Lug Lid |

| 18 |

292 |

271 |

320 |

0.28-0.33 |

240 |

Lug Lid |

| 20 |

292 |

271 |

370 |

0.28-0.33 |

228 |

Lug Lid |

| 22 |

292 |

271 |

400 |

0.28-0.33 |

216 |

Lug Lid |

| 25 |

292 |

271 |

440 |

0.28-0.33 |

216 |

Lug Lid |